Chemical Compositions

Wire GradeDiameterrange(mm)Chemical Compositions

CSiMnPSCrVCo

SWOSC-V

0.8-8.0

0.51-0.59

1.20-1.60

0.50-0.80

-0.025

-0.025

0.50-0.80

-

-

SWOSC-VH

2.0-6.5

0.63-0.68

1.30-1.60

0.60-0.80

-0.025

-0.025

0.50-0.80

-

-

SWOSC-VHV

2.0-6.5

0.63-0.68

1.20-1.60

0.50-0.80

-0.025

-0.025

0.50-0.80

0.10-0.20

-

SWOSC-VHS

2.0-6.5

0.63-0.68

1.80-2.20

0.70-0.90

-0.025

-0.025

0.50-0.80

0.05-0.15

-

SWOSC-VHR

2.0-5.0

0.63-0.68

2.10-2.30

0.50-0.70

-0.025

-0.025

1.10-1.30

0.10-0.20

0.10-0....

继续阅读完整内容

请查看下方广告以解锁文章剩余内容

广告加载中...

Chemical Compositions

| Wire Grade | Diameter range (mm) | Chemical Compositions | |||||||

|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | Cr | V | Co | ||

| SWOSC-V | 0.8-8.0 | 0.51-0.59 | 1.20-1.60 | 0.50-0.80 | -0.025 | -0.025 | 0.50-0.80 | - | - |

| SWOSC-VH | 2.0-6.5 | 0.63-0.68 | 1.30-1.60 | 0.60-0.80 | -0.025 | -0.025 | 0.50-0.80 | - | - |

| SWOSC-VHV | 2.0-6.5 | 0.63-0.68 | 1.20-1.60 | 0.50-0.80 | -0.025 | -0.025 | 0.50-0.80 | 0.10-0.20 | - |

| SWOSC-VHS | 2.0-6.5 | 0.63-0.68 | 1.80-2.20 | 0.70-0.90 | -0.025 | -0.025 | 0.50-0.80 | 0.05-0.15 | - |

| SWOSC-VHR | 2.0-5.0 | 0.63-0.68 | 2.10-2.30 | 0.50-0.70 | -0.025 | -0.025 | 1.10-1.30 | 0.10-0.20 | 0.10-0.30 |

Mechanical Properties

| Nominal Dia 1) (mm) | Tensile Strength (N/mm²) | Tolerance (mm) | Ovality (mm) | ||||

|---|---|---|---|---|---|---|---|

| SWOSC-V | SWOSC-VH | SWOSC-VHV | SWOSC-VHS | SWOSC-VHR | |||

| 2.0 | 1910-2060 | 2110-2210 | 2110-2210 | 2160-2260 | 2210-2310 | ±0.02 | 0.02 |

| 3.0 | 1860-2010 | 2060-2160 | 2060-2160 | 2110-2210 | 2160-2260 | ±0.02 | 0.02 |

| 4.0 | 1810-1960 | 2010-2110 | 2010-2110 | 2060-2160 | 2110-2210 | ±0.03 | 0.03 |

| 5.0 | 1760-1910 | 1960-2060 | 1960-2060 | 2010-2110 | 2060-2160 | ±0.03 | 0.03 |

Double Eddy Current Test

For 2.1~6.0mm in diameter, double eddy current tests, i.e. stationary and rotating types, are applicable.

Packing

| Wire Diameter(mm) | Coil Size(mm) | Coil Weight(kg) | ||

|---|---|---|---|---|

| Inner Diameter | Outer Diameter | Lapped Coil | Coil with Carrier | |

| 0.8-1.2 | 300 | 580 | 50 | 100 |

| 1.3-1.9 | 650 | 1100 | 100/200 | 400 |

| 2.0-2.9 | 650 | 1100 | 100/200 | 400 |

| 1000 | 1500 | 200/400 | 800 | |

| 3.0-5.5 | 1000 | 1500 | 200/400 | 800 |

| 5.6-8.0 | 1300 | 1500 | 200/400 | 800 |

Technical Note

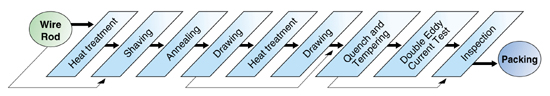

(1)Manufacturing Process

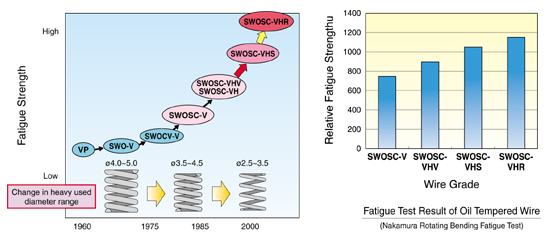

(2)Fatigue Strength

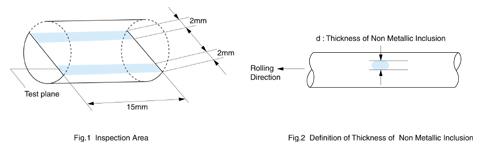

(3)Microscopic Test of Non-Metallic Inclusions (Max.T Method)

The samples are taken in wire rod state and those longitudinal sections are polished. For each sample, both the top and bottom surface zones that are from the surface to 2mm inside and having 15mm length shall be inspected (i.e. 60mm² area, see fig.1). For each heat, 10 samples shall be inspected and maximum thickness of observed non- metallic inclusions (see fig.2) shall not be 15μm or larger.